Emergence of ferromagnetism due to charge transfer in ...

Thus, a superhighenergy ball mill can be used to control a range of charge and spin states in transition metal oxides with high pressure, yielding the emergence of a large spectrum of ...

WhatsApp)

WhatsApp)

Thus, a superhighenergy ball mill can be used to control a range of charge and spin states in transition metal oxides with high pressure, yielding the emergence of a large spectrum of ...

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll ...

Ball Charging amp Grinding Media Handling. Automatic Ball Charge Handling Systems Safe sorting and handling of grinding media in the range 27mm to 150mm diameter Tonnes of grinding media normally in the form of steel balls are consumed by all process plants having mills as part of their comminution process The handling of heavy steel balls .

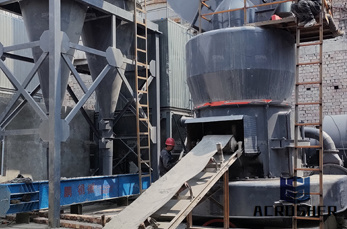

We offer autogenous (AG), semiautogenous (SAG), ball, rod, and pebble mills in sizes ranging from kWs up to 30+ MW. Our product range also includes a number of unique solutions, including the world''s largest acidresistant grinding mills, which can operate with extremely corrosive slurry.

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotati

Ball Mill Charge. Ball mill charge grinding ball charge and ore charge volume is a variable, subject to what is the target for that type of mill also is a factor as if it is an overflow mill subject to the diameter of the discharge port is usually up to about operated lobster tennis machine lobster tennis.

Rod Mill Charge: Typically 45% of internal volume; 35% – 65% range; Bed porosity typically 40%. Height of bed measured in the same way as ball mills. Bulk density of rods = tons/m3; In wet grinding, the solids concentration 1s typically 60% – 75% by mass.

Optimisation Of The Ball Charge In Mills For Cement Grinding . Optimisation of the ball charge in mills for cement grinding article in cement international 764247 november 2009 with 29 reads how we measure reads process diagnostic studies for cement mill used machines for cement grinding in large number of cement plants in this paper authors are covering the process diagnostic study of ball

A Planetary Ball Mill for rapid fine crushing of soft, hard, brittle and fibrous material to end fineness <1µm Quick and easy to clean Rapid fine crushing Easy exchange of grinding jars and balls Grinding jars and balls made from a wide range of materials available Grinding jar volume up to 500cc Progr. control End fineness < 1µm CEcertified Planetary Ball Mills for fine grinding of soft ...

Figure 5. High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be chosen in isolation.

Optimization Of Mill Performance By Using . Stresses generated in the ball charge increase which may result in spalling of balls and blocking the grate discharge optimization of mill performance by using online ball and pulp measurements by b clermont and b de haas synopsis ball mills are usually the largest consumers of energy within a mineral concentrator

Stresses, generated in the ball charge, increase, which may result in spalling of balls and blocking the grate discharge. Optimization of mill performance by using online ball and pulp measurements by B. Clermont* and B. de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator.

Jan 15, 2015· Page 1 of 2 How many balls for the mill? posted in Tools and Tooling: Hi there, Ive got a 2L ballmill and I usually make around 100g of BP at, if I use lead balls, how many do you suggest me to put in there? I can also choose between and diameter (15/32th or 19/32th).The weights are and 20g per ball. Best Regards

A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rods. A tube mill is a revolving cylinder of up to five diameters in length used for fine pulverization of ore, rock, ...

BallMill Base with Ventilated MotorCover Installed BallMill Base with Ventilated MotorCover Removed The BallMill Drive System Looking inside the mill''s motor compartment, you can now see the motor, with a small fan and pulley on its shaft. That small pulley is connected by a drive belt to a large pulley which is mounted on the unit''s drive ...

Sep 01, 2013· For the same amount of ball charge, the number of balls in the mill decreases as the ball size increases. Thus, the S values are lower for larger balls. However, larger balls are capable of breaking large particles; therefore, the size at which the S value becomes maximum, x m, increases as the ball size becomes larger.

Ball Charge Mill India. 3. complete plant of hamedan 100 m3 blast furnace, iran 4. complete plant for essa cement company, pakistan annual capacity 150,000 tons 5. medan floating glass plant, indonesia daily melting capacity 300 tons 6. complete plant for long tho cement manufacturing plant, vietnam 7.

Ball Mills Charge. Test mills used for media sizing investigations need to be reasonably large at least m in diameter was suggested depending on size of balls and ore being tested. ball surface wear rate is approximately constant but with variations due to hardness and other factors. consumption is closely related to total ball charge surface.

Vertical Roller Mills (VRM). Roller press with Ball mill. Ball Mill. Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills.

More convenient pickup options in Balls Mill at no extra charge to you. Have your package kept securely and ready for pickup at your convenience at a nearby FedEx Ship Center or FedEx Office location in Balls Mill. Delivery options. Our Company. About FedEx. Our Portfolio. Investor Relations. Careers.

material charge occupying 25 percent of the mill cylinder will give the best results. The rule of thumb for wet milling is to fill the mill to about an inch over the media level. Instructions for Installation, Operation And Maintenance for Ball Mills I. Installation A. Check the selected mill site to insure clearance for the proposed mill. It is

Dec 12, 2016· If P is less than 80% passing 70 microns, power consumption will be. Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a .

Ball Mill Charge Calculation Circulating load calculation made in a mill. ball mill circulating load calculation circulating load calculation formula mineral processing oct 23, 2016 here is a formula that allows you to calculate the circulating load ratio around a ball mill

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

WhatsApp)

WhatsApp)